Rotational Moulding - Hydraulic Tank Design.

This article has been written to fuel the imagination of design engineers working on Hydraulic Tanks. One of my clients, a Rotational Moulding manufacturer 'Amber Plastics', has expertise and a great deal of experience in the field. The Article applies my knowledge of industrial design and engineering with their specialist manufacturing expertise to highlight the advantages of Rotational Moulding Hydraulic tanks for industrial machinery, vehicles and construction equipment.

Hydraulic Tank / Reservoir Design for Rotational Moulding

The rotational moulding of hydraulic tanks can have many benefits, including reducing manufacturing costs and increasing hydraulic system performance whilst giving the designer more freedom. The simplest rotational moulded hydraulic tanks serves the same purpose as conventional, fabricated steel tanks but with substantial manufacturing cost savings. Rotational moulding really makes a difference when the designer builds in additional benefits, making them more than just a vessel for liquid storage.

Performance and Function Considerations of Hydraulic Tanks

Hydraulic tanks need to contain oil safely over long periods and in all extremes of operating conditions, the tank must prevent contamination.

- Tanks made from a single rotational moulding won’t have weak joints that can crack due to vibration or thermal stresses.

- The thermoplastics used are inherently resistant to chemical deterioration and corrosion free, internally and externally. Steel tanks are prone to rust, internally from moisture condensing from the oil and externally when paint or surface treatment degrade.

A hydraulic tank forms part of thermal performance of a hydraulic circuit. At first glance a steel tank will conduct more heat from the oil, but the skilled designer can reverse this.

- Moulding in fins and ribs will give a larger external surface area and provide additional passive cooling.

- Fins and ribs provide structural strength so wall thickness can be reduced therefore increasing thermal conductivity.

- If parts of the tank surfaces are used as an external component the cooling effect can be increased as well as providing opportunities for aesthetic enhancements.

- If the airflow around a well designed tank is sufficient, it will be possible to reduce or even eliminate the need for a radiator type oil cooler.

Hydraulic tanks need to circulate a flow of oil in such a way that all the available oil is used in the regular cycle of the machine's operation. This prevents overuse of a small amount of the available oil.

- Rotational moulding allows the designer to incorporate a physical path from the Return to the Flow so all the oil is cycled through the tank.

- As almost any tank shape can be achieved, the traditional restraints of hose and pipe runs in cramped compartments don’t have to compromise the need for a good flow through the tank.

Hydraulic tanks have an important role in maintaining the condition of the oil. Good oil reduces system and pump wear, increases service intervals whilst maintaining excellent hydraulic performance.

- A rotational moulding can be moulded with integrated baffles to produce a sufficiently long, slow flow of oil through the tank. Contaminants such as solid particles have enough time to sink to the bottom and air will rise out.

- A low point sump can be moulded in with a threaded insert to fit a tap-off drain so water can be removed along with small solids.

- Rotational moulding can form a threaded (internal or external) access aperture that can be sealed with a large diameter cap. This would allow a service engineer to reach in to the tank for cleaning and to give access to any internal components such as a suction strainer/filter.

The volume of oil used in the circuit is a factor that affects the thermal performance and oil condition. (Twice the oil halves the problems?).

- Rotational moulding allows a hydraulic tank to be designed for economical production whilst take advantage of all the available space.

- A rotationally moulded hydraulic tank can be formed to fit around other machine components and even become part of the external structure.

- The volume of oil contained can be increased with a resulting increase in long term system performance.

Hydraulic tanks have to incorporate many fittings; inlets, outlets, filler caps, sight glasses, level floats, mounting points etc.

- During the rotational moulding process threaded inserts of any size can be moulded in to the material of the tank.

- The inserts are designed to transmit torsional stress over a wide area and provide pressure sealed mountings for any fittings or components.

- If extra structural strength is required, mouldings can incorporate details or reinforcing inserts. In addition fittings can be recessed below the external surface or raised moulded areas can providing the fittings with protection from physical damage.

All these points give designers scope to create innovative hydraulic tanks. Rotational moulding allows engineers and designers to produce radical designs with improved hydraulic performance, reduced component cost, lower assembly times and increased reliability. All it needs is for engineers to embrace the rotational moulding process and to think outside of the box.

If you have any general comments about this article, please nip over to the idostuff blog.

For specific enquiries about manufacturing a tank or any rotational moulding project, please contact Amber Plastics Ltd (Chesterfield UK) the rotational moulding experts.

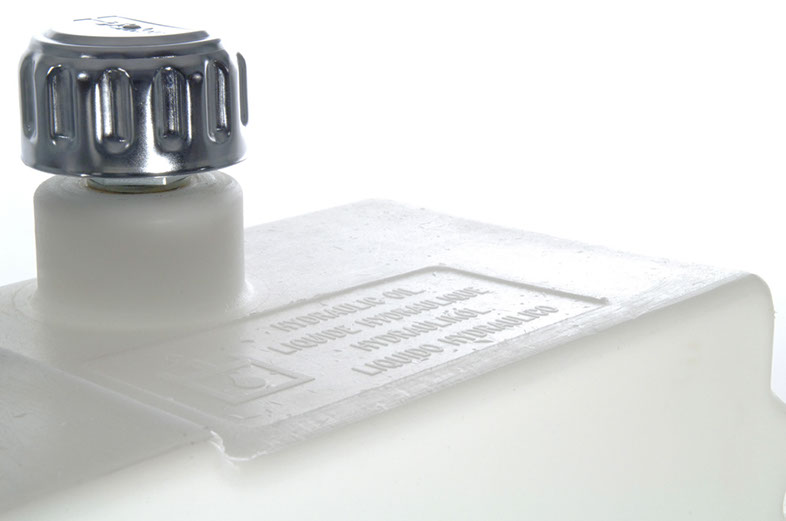

Rotational Moulded Tank Images

Internal and external threads can be Rotational Moulded in to make perfect access ports . Metal inserts are moulded in for fittings and mounting points.

Almost no limits to external shape and internal details so yes, internal baffles can be moulded.

Where space is tight in a compartment, tanks can be moulded to fit in every available space. Giving the opportunity for increased oil volumes.

External surfaces can carry fine detail and textures as well as shapes so tanks can form part of the equipment exterior giving the designer scope for some creative aesthetic designs.

Notes on the Rotational Moulding Pictures.

Taken by myself a A.G. Bell copyright 2012. in my capacity as a commercial photographer agbimages. So please don't rob them! If you do want to use them on-line, credit them with a "follow" Link back here.

So another insight in to the stuff that I do, this time in one of my professional capacities.